Mastering 45° Bevel Cuts with Laser Precision

45-Degree Bevel Cutting

In the manufacturing processes of shipbuilding, construction machinery, oil pipelines, and other industries, bevel machining of thick steel plates is an indispensable procedure. It involves processing and assembling the weld-prepared parts of workpieces into a specific geometric bevel shape to ensure firm welding. Compared with traditional processes, bevel cutting and blanking reduce multiple procedures.

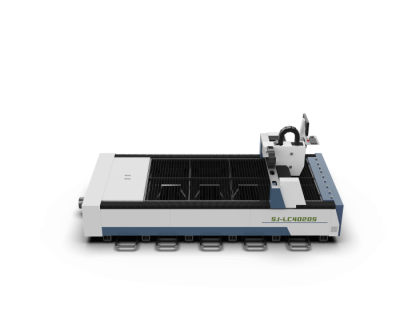

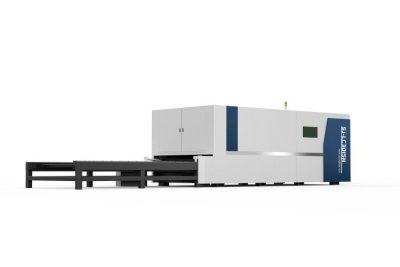

A bevel laser cutting machine can achieve cutting at angles ranging from 1° to 45°, forming the bevel in one step. It completes the bevel machining that traditionally requires multiple processes such as cutting and milling in a single operation, significantly improving efficiency and saving resources.

Characteristics | Functions | Advantages |

Angle Control | Adjust the laser cutting angle to the precise 45° for miter joints. | Ensure tight and accurate corner joints with minimal effort. |

Precision Cutting | Use a focused laser beam to ensure clean and sharp edges. | Deliver smooth cuts that require no additional finishing. |

High-Efficiency cutting | Enable high-speed cutting capability. | Reduce cutting time while maintaining high precision. |

In the manufacturing processes of shipbuilding, construction machinery, oil pipelines, and other industries, bevel machining of thick steel plates is an indispensable procedure. It involves processing and assembling the weld-prepared parts of workpieces into a specific geometric bevel shape to ensure firm welding.

The bevel cutting process of tube laser cutting machines enables zero-gap welding. During subsequent assembly, no additional processing is required, reducing procedures and significantly cutting down labor and material costs. Tube laser cutting machines are gradually becoming the primary replacement for traditional metal cutting equipment. They empower enterprises to achieve diverse manufacturing functions, enhance production efficiency, and save substantial production costs.

1.Precise and Controllable Cutting Angles: Bevel laser cutting machines support multiple preset cutting angles, including 0° - 45° bevel cuts, as well as V-shaped, Y-shaped, X-shaped, K-shaped, and gradient bevel cuts. This streamlines production processes and eases welding operations.

2.Maximum Material Savings with Airborne Cutting: By addressing the material-saving challenges of K-bevel cuts on plates, this technology maximizes material utilization, achieving unprecedented savings.

3.High-efficiency and High-precision Cutting: Compared to traditional methods, bevel laser cutting machines significantly boost cutting efficiency, shorten processing time, produce smooth cut edges, and incur lower processing costs.

Compared with traditional processes, bevel cutting and blanking reduce multiple procedures.

A bevel laser cutting machine can achieve cutting at angles ranging from 1° to 45°, forming the bevel in one step. It completes the bevel machining that traditionally requires multiple processes such as cutting and milling in a single operation, significantly improving efficiency and saving resources.