![1748928894605559.jpg 06.03.jpg]()

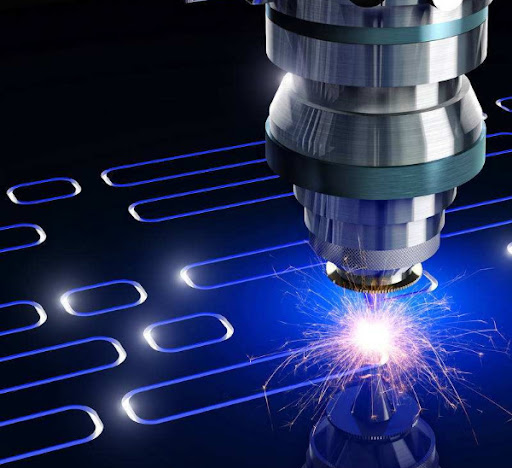

The beam transmission system of a laser cutting machine is a key component to ensure that the laser beam accurately hits the material to be cut. This system is typically composed of a combination of mirrors and optical fibers, each playing a specific role in maintaining the integrity and precision of the laser beam.

1)Mirrors and optical fibers for guiding the laser beam

In CO₂ laser cutting systems, mirrors are usually used to reflect and guide the laser beam from the laser source to the cutting head. These mirrors must be precisely aligned to ensure that the beam remains focused and powerful throughout the path.

In contrast, fiber laser systems use optical fibers to transmit laser beams. Optical fibers offer greater flexibility and higher efficiency in guiding laser beams, especially for long distances or complex paths.

2)The importance of alignment and calibration

Proper alignment and calibration of the beam transmission system are crucial to achieve optimal performance. Improper calibration can lead to reduced beam intensity, decreased cutting quality, and even damage to the machine.

Regular maintenance and calibration checks are necessary to ensure that the mirrors and optical fibers are correctly aligned. Advanced laser systems often include automatic alignment and calibration functions, which help maintain consistency and reduce the need for manual adjustments.

3)Common problems and troubleshooting

Some common issues affecting the beam transmission system include beam deviation, dirt or damage to mirrors/optical fibers, and power loss.![1748929019590476.jpg 1748929019590476.jpg]()

The motion control system is an important component of a laser cutting machine, responsible for precisely moving the laser head and workpiece to achieve accurate cutting.

This system includes various types of motors and control systems that work together to ensure that the laser cuts along the desired path with high precision and speed.

1)Overview of the numerical control system

The computer numerical control (CNC) system is the backbone of motion control for laser cutting machines. These systems convert design files into precise instructions that control the movement of the laser head and worktable.

The CNC system coordinates time and motion to ensure that the laser cuts along the exact path specified in the design. Advanced CNC systems can handle complex geometries and support high-speed cutting while minimizing errors.

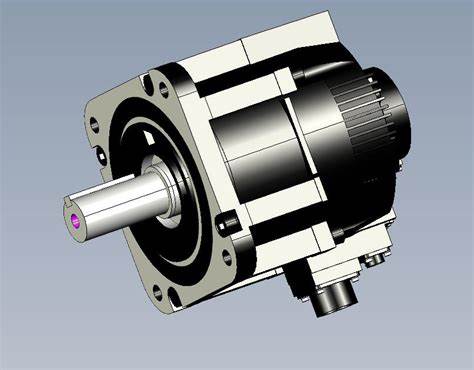

2)Types of motors used![1748930682391196.jpg 1748930682391196.jpg]()

Servo motorsServo motors can precisely control position, speed, and torque, making them suitable for high-precision applications. Known for their accuracy and response speed, servo motors are ideal for complex and delicate cutting tasks.

They are equipped with feedback systems such as encoders to continuously monitor motor position and make corresponding adjustments to maintain accuracy. Stepper motors

Stepper motors are typically used in less demanding applications. They move in discrete steps and can provide good position control, but may lack the speed and precision of servo motors.

Stepper motors are usually less expensive and simpler to use, making them suitable for entry-level laser cutting machines. However, they do not have a feedback system, which may lead to missed steps and reduced accuracy under high-speed or high-load conditions.