Machines are to be shipped? How can we ensure the safe delivery?

At SL LASER company, every step of our process is dedicated to making our efforts visible and ensuring customer satisfaction – this is the unwavering focus of our entire team. Today, we’ll take you through our shipping process in detail, which consists of two main phases: Pre-Packing Preparation and Packing Operations.

1. Pre-Packing: Meticulous Preparation Where Every Detail Counts

1)Quality Inspection: Rigorous Machine Quality Control

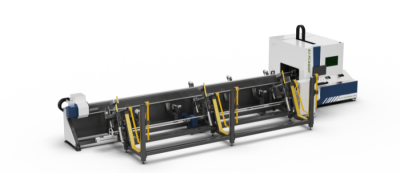

Pre-packing preparations require close team coordination. Upon confirming the shipping schedule with customers, we initiate preparations at least two weeks in advance. Our primary task is quality inspection: Once machines are completed, our staff conducts comprehensive checks. This includes examining the machine’s exterior, testing operational procedures against standards, and scrutinizing both critical components and minor details. Specifically for tubes the customer will process, like the Laser Tube Cutting Machine, we conduct repeated tests using the exact tube specifications required like round, square, or irregular tubes, to ensure full compliance with customer requirements.

2)Packing: Multi-Layer Protection for Machine Safety

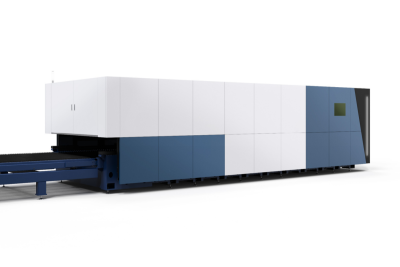

Though seemingly routine, packing directly impacts the machine’s condition upon delivery. We begin by thoroughly cleaning every component to remove debris. Moving parts like guide rails are lubricated to prevent rust, and chillers are drained to avoid freezing during sea transit. Next, the entire machine is wrapped in transparent film, covered with thick protective foam, and sealed with another film layer to block moisture and prevent corrosion.For important components of the Fiber Laser Pipe Cutter, such as the laser, optical fiber, and laser head, we will provide additional enhanced packaging to ensure that they will not be damaged or knocked during transportation.

All packed items are clearly labeled for easy identification.

2. Packing Process: Precision Execution for Secure Transit

After packing, staff never proceed directly to loading. They meticulously cross-check items against the packing list to confirm completeness. During loading:Placement of each component is strategically planned to balance container weight distribution.

The anchor point is firmly fixed to ensure that no collision occurs during transportation. maximizing cost efficiency for customers – a key competitive advantage!

The above outlines SL LASER’s complete shipping workflow. Every step is diligently executed by our team to deliver high-quality machines. We firmly believe that genuine customer-centricity embodies our greatest sincerity and competitiveness. From quality inspections beginning pre-shipment to meticulous loading checks and space optimization – each phase reflects our commitment to prioritizing customer needs. Keeping customer interests at heart, translating product quality into action, and earning trust through tangible results – this is the core of SL LASER’s sustainable growth.