How to Know which Laser Machine Suitable For Us ?

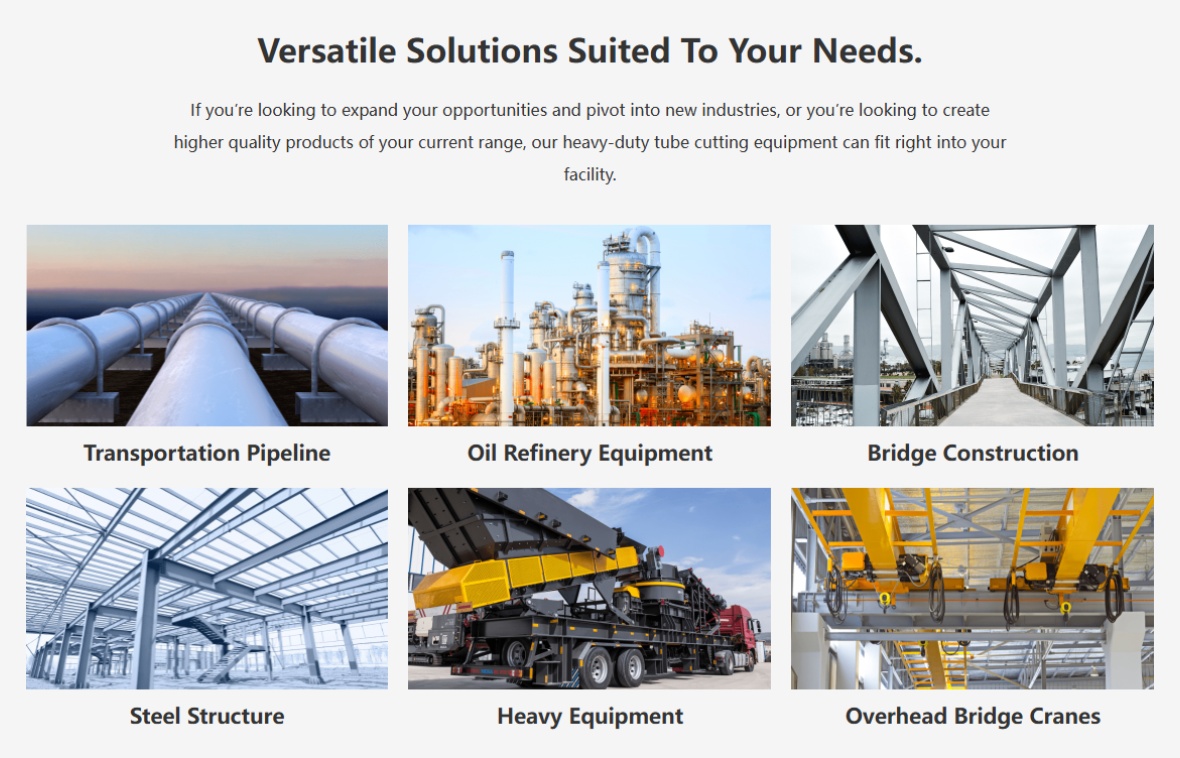

For manufacturers in the metal processing industry, or companies that outsource metal tube cutting services, purchasing a suitable laser cutting machine is a crucial investment decision. It's essential to determine the right laser cutting machine and its price for metal tube cutting.

We must clearly define our specific processing needs.

The materials : Carbon Steel, Stainless Steel,Aluminum,Copper or other metal materials ?

The Thickness: the min thickness and the max thickness ?

The Cutting quantity: How many Pipes you will cut per day ?

The Precision : very high ?

The Size: Pipe Length and Diameter ?

Automatic or semi-automatic ?

Cut off only or many holes or Bevel Cutting ?

your cutting size?

The Metal Pipe Cutting Machine Models

SL-PC1065J /SL-PC1085J Round Pipe Cutting Machine

SL-PC6012F /SL-PC6017FS / SL-PC6024F Fully automatic or Semi-automatic Fiber Laser Cutter

SL-PC6024D Metal Pipe Laser Cutting Machine

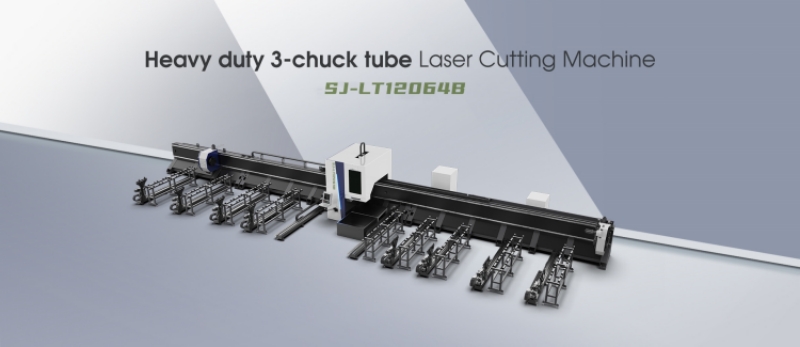

SL-PC12036B Three Chuck Heavy Duty Laser Pipe Cutting Machine

SL-PC12064 H Beam Fiber Laser Cutter

SL-PC12090XB Rotary Head Fiber Laser Cutting Machine

Determining the model and configuration of a laser cutting machine requires considering many factors; it cannot be decided based on just one aspect. Therefore, the price varies widely. For example, what is the weight of the machine bed? Has it been heat-treated? Has it been quenched? All these factors affect the cost. However, those unfamiliar with laser equipment may not be able to discern these differences. Therefore, it's crucial to thoroughly understand and compare different options before purchasing equipment. Simply choosing the lowest-priced machine is not advisable, as some hidden low-configuration features may not be apparent initially, but will become evident as the machine continues to operate, problems will gradually emerge, and most of these problems are impossible to rectify.

With years of experience in laser cutting equipment, we uphold a responsible attitude towards our customers, meticulously crafting each piece of equipment. We track the entire production process, strictly control quality, and provide timely installation guidance upon arrival at the customer's site. This ensures that every customer can use each machine with peace of mind and that each machine can quickly create value for their clients.