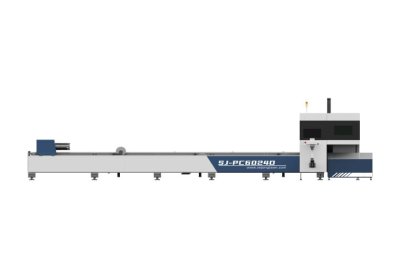

SL-HW1500M Refrigerant Laser Welding Machine.

Three major advantages of the SL-HW1500M:

Adopting refrigerant direct cooling technology

Easy to use and move

Reduced cost and high cost performance

Adopting refrigerant direct cooling technology:

with an operating temperature range of -10℃~50℃. It uses a refrigerant self-cooling circulation system and a high-performance condensing and heat-dissipating device to continuously output heat. It can emit light continuously in extreme environments.

Easy to use and move:

Compared with traditional water-cooled welding machines, the refrigerant laser welding machine has no built-in water tank, is more than 60% lighter in weight and smaller in size, making it convenient for customers to better handle complex welding tasks at different work locations.

Reduced cost and high cost performance:

Compared with traditional water-cooled welding machines and air-cooled welding machines, under the same power condition, energy saving and electricity saving can reach more than 30%.

Name | Water Cooling Welder

| Water Cooling Welder

| Water Cooling Welder

|

Machine Size | Big | Small | Small |

Machine Size | Heavy | Light | Light |

Portability | Mediocre | Good | Good |

Cooling effect | Good | Mediocre | Good |

Continuous Operation | Long Time | Short Time | Long Time |

Stability | Good | Mediocre | Good |

With core performance and functional effectiveness entirely consistent with those of industry-leading brands, we have achieved price advantages through cost optimization. Choosing us means obtaining refrigerant self-cooling laser welding machines of equivalent value at a lower cost.

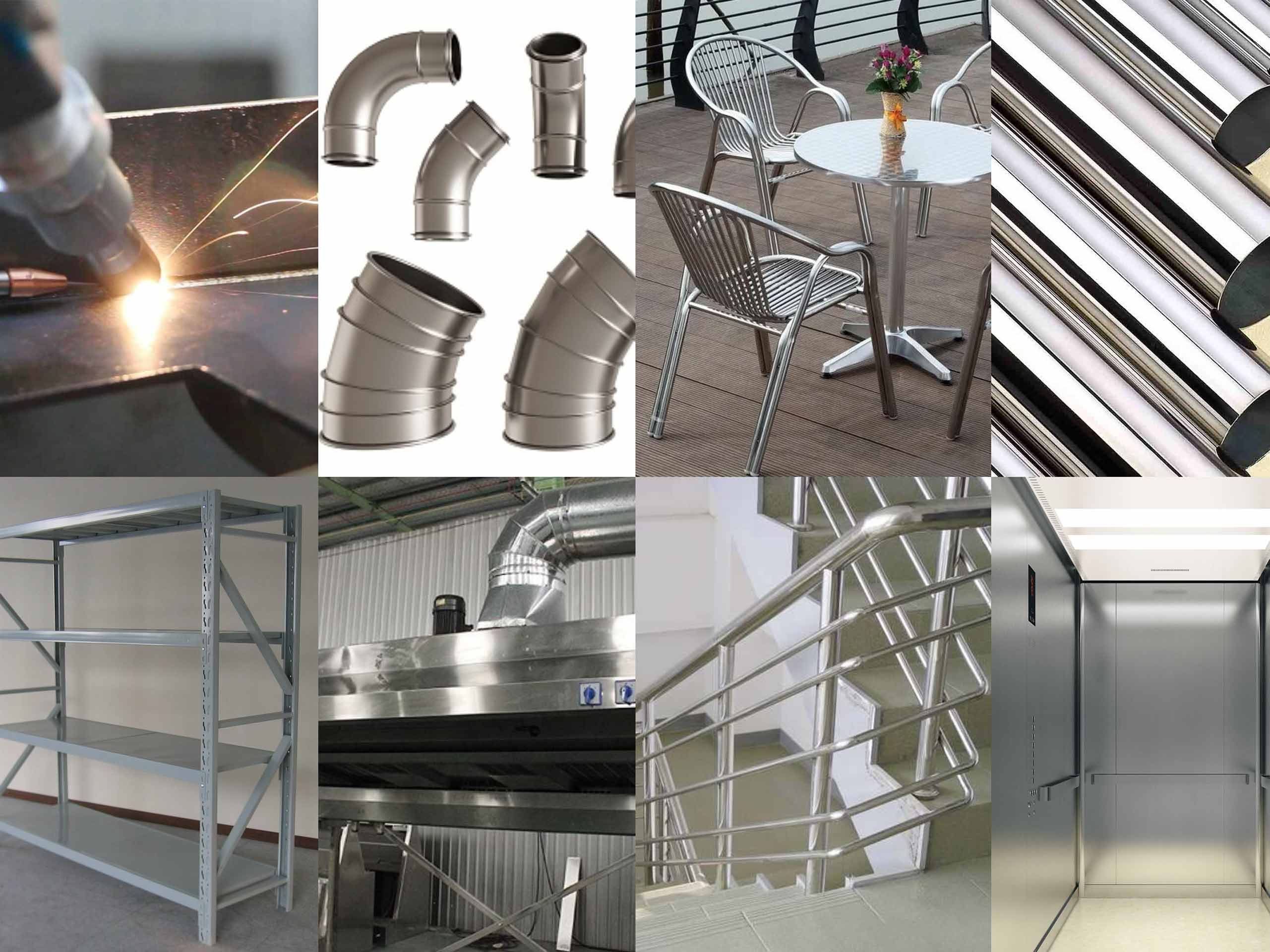

Applicable industries:

Kitchenware, sheet metal processing, stainless steel products, air ducts, shelves, handicrafts, stair handrails, chassis and cabinets, furniture and home appliances, etc.