Discover the Fiber Laser Pipe Cutting Machine

Understanding Fiber Laser Pipe Cutting Machines:

1.Differences from other laser cutting machines

Compared with CO₂ laser cutting machines and YAG laser cutting machines:

CO₂ laser cutting machines have high maintenance costs. Their front and rear mirrors are expensive, and the turbine bearings have a service life of only 8,000 hours, with replacement costs reaching 80,000 yuan per pair. Their photoelectric conversion rate is only 8%~10%, resulting in higher processing costs. Both traditional CO₂ and YAG laser cutting machines suffer from low photoelectric conversion rates, high operating costs, significant thermal effects, and high maintenance costs. These drawbacks limit their application in high-power, high-precision, and long-term continuous production scenarios.

For manufacturers requiring extremely high precision and efficiency, fiber laser cutting machines will eventually replace most of the CO₂ laser cutting machine market. The advantages of fiber laser cutting machine lasers lie in miniaturization, intensification, high brightness, and high conversion rates. In thin-plate processing, fiber laser cutting machines of the same power are 2~3 times more efficient than CO₂ laser cutting machines.

2.Problems in processing complex materials:

High-reflectivity steel and galvanized materials can lead to inconsistent cutting quality.

Traditional methods take excessive time, with tasks taking a full day to complete.

Low efficiency increases operating costs and material waste.

3.Solutions

SL-PC6012F automatic fiber laser cutting machine.

Material compatibility

Easily processes reflective materials such as galvanized steel.

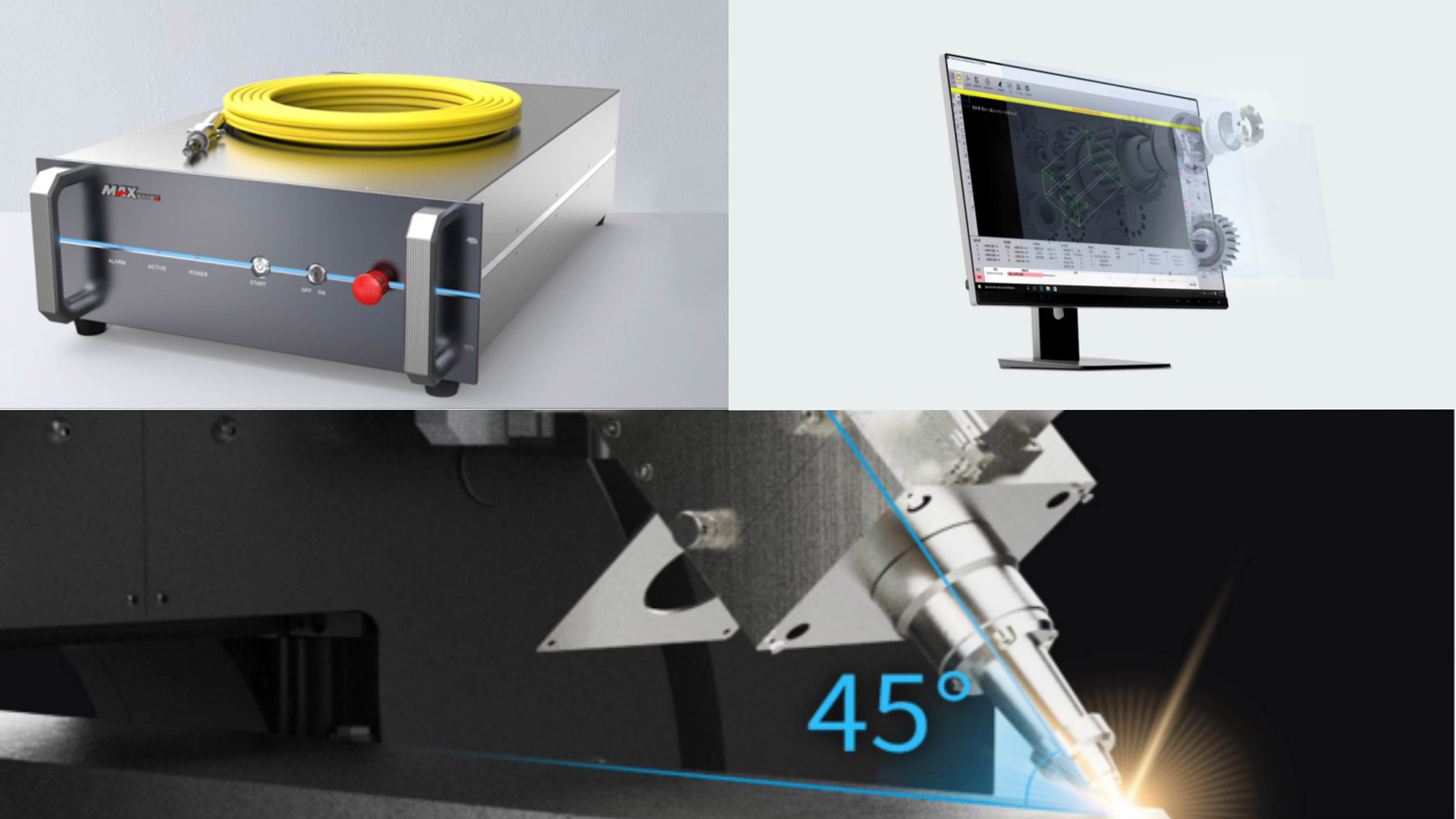

Oscillating cutting head

Enables 45° dead-angle cutting, enhancing flexibility in complex cutting tasks.

FSCUT numerical control system

A full-featured control system specially designed for laser cutting, reducing task completion time by 80%. It integrates integration and intelligence, ensuring high-speed and high-precision operation. Equipped with comprehensive diagnostic functions for quick fault location, and supports multi-format part import, etc.

F3000W fiber laser source

Boasts a photoelectric conversion efficiency of 25%~30%, with industrial-grade top-level pulse power/energy stability. Its long-life and high-precision design ensures a pump source lifespan of over 100,000 hours. It offers faster speed and near-perfect processing results, with beam quality optimized for specific applications.

FAQ:

1. Q: What is a fiber laser pipe reducing computer and how is it specific from usual slicing machines?

A: A fiber laser pipe slicing laptop makes use of a high-power fiber laser to reduce steel pipes with precision and speed. Unlike standard mechanical or flame slicing methods, fiber lasers provide greater accuracy, cleaner edges, quicker slicing speeds, and much less cloth waste. They are additionally greater energy-efficient and require minimal maintenance.

2. Q: What substances can be reduce the usage of a fiber laser pipe reducing machine?

A: Fiber laser pipe reducing machines are best for reducing a extensive vary of steel pipes, consisting of stainless steel, carbon steel, aluminum, copper, and brass. They can cope with each thick and thin-walled pipes with exquisite slicing quality.

3. Q: What kinds of pipes can the laptop handle?

A: These machines are succesful of slicing quite a number pipe shapes, such as round, square, rectangular, oval, and special-shaped profiles. Advanced fashions regularly encompass automated clamping and rotary structures to accommodate complicated pipe geometries.

4. Q: Is it hard to function a fiber laser pipe slicing machine?

A: No, most fiber laser pipe slicing machines come with simple software program and intuitive interfaces. Operators can effortlessly enter reducing parameters, load pipe profiles, and display the manner in real-time. With minimal training, customers can shortly emerge as expert in working the machine.

5. Q: What are the frequent purposes of fiber laser pipe reducing machines?

A: These machines are extensively used in industries such as automotive, aerospace, health equipment, metal structure, furnishings manufacturing, and construction. Their potential to produce high-precision cuts with minimal post-processing makes them integral for modern-day steel fabrication.