Robotic Welding vs Manual Welding: Which Provides Greater Efficiency?

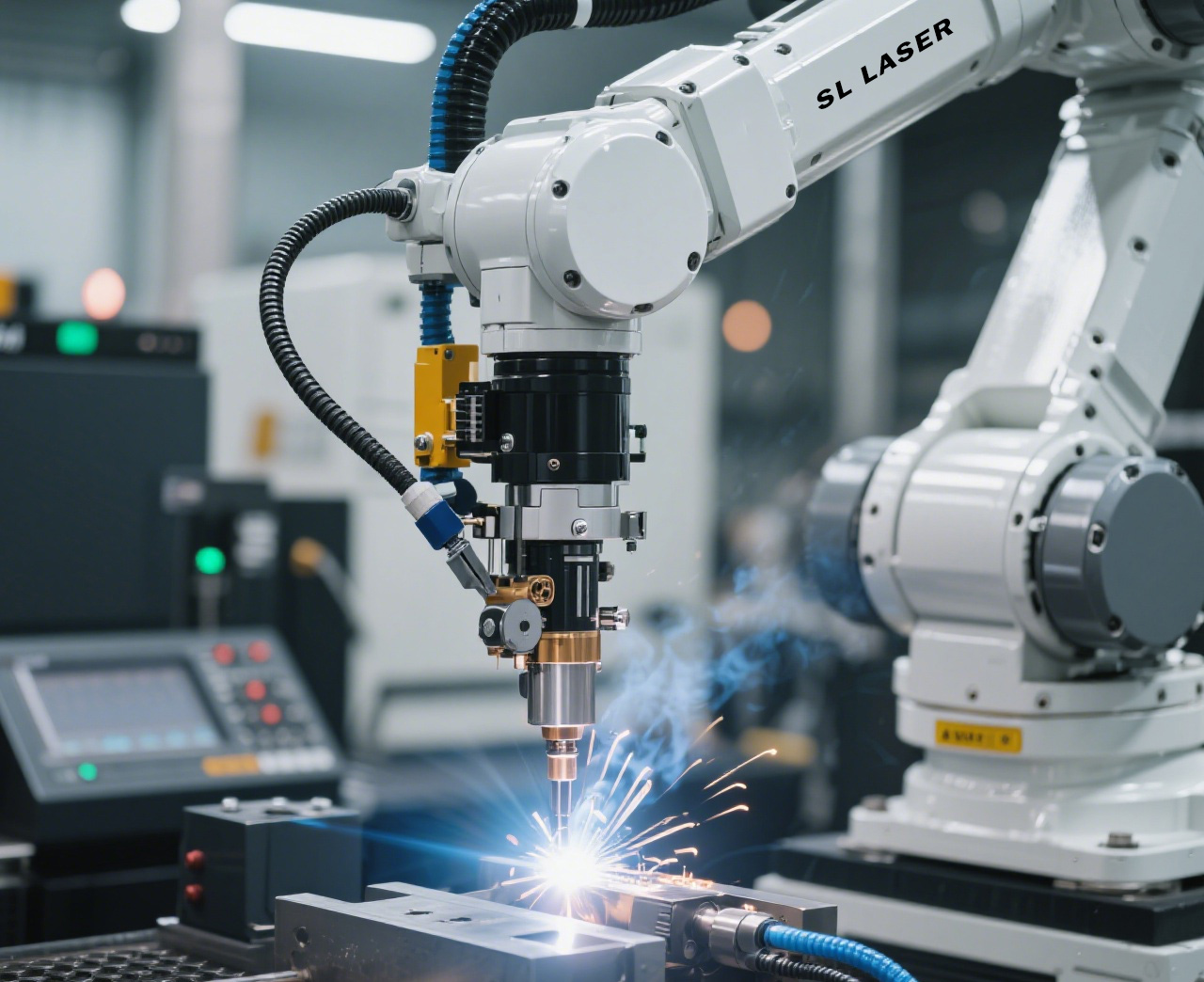

With the continuous updates in the industrial manufacturing field, more and more customers have requirements for high efficiency and high quality in welding. In order to cater to the market, robotic laser welding machines, relying on their superior performance, have become a hot product in the current industrial field.

Nowadays, many customers still use manual welding for welding. However, with the requirements for welding quality, time costs, etc., manual welding can no longer meet the needs.

High labor costs

Manual welding requires a large number of skilled workers, and the costs of workers' wages and training are relatively high. As labor costs increase, the overall production costs of enterprises also rise accordingly.

Unstable welding quality

The quality of manual welding is easily affected by factors such as workers' technical proficiency, fatigue levels, and environmental conditions, leading to inconsistent welding quality. This instability may affect the qualification rate of the final products.

Risk of worker injuries

Workers in the process of welding operations, will face dangers such as working in extreme environments and arc light or other harmful gases, easily causing irreversible safety accidents and physical harm. And the use of robot welding operations, then greatly reduces hidden dangers in this aspect.

Low production efficiency

Manual welding is usually slow, and workers' efficiency tends to decrease after long hours of work. This makes it difficult to arrange the production cycle reasonably and affects the overall production efficiency.

What are the advantages of robotic laser welding machines?

Let's introduce them as follows.

●Compared with traditional argon arc welding, the speed of robotic laser welding is increased by 2-5 times, with lower power consumption and material usage, and the welding quality is also very stable.

●Due to the small heat-affected zone of welding, it can better ensure the high quality of welded products.

●It helps customers eliminate the grinding process; products can be finished and delivered directly after wire drawing. This also allows customers to save the input costs of grinding labor and equipment, thereby making their products more competitive in the market.

●This workstation has high flexibility and can weld 3D curved surfaces or special-shaped workpieces, when matched with special tooling, linkage workbenches, etc.

●Laser welding produces less smoke and radiation, which protects the operating environment and ensures high safety.

●It can meet high welding quality requirements, such as the weld width not exceeding one-tenth of the plate thickness.

●Laser hybrid welding can be selected for special processes.

Product applications:

Kitchen appliances

Washing machines

Water heaters

Pressure vessels

Precision cabinets

Elevators and escalators

New energy vehicle motors

Servo motors

3D precision sheet metal