Can a CO₂ Laser Cutter Cut Metal? Let’s Find Out

If you’re new to laser cutting, you might wonder: can a CO₂ laser cutter handle metal? Let’s break it down simply.

How CO₂ Laser Cutters Work with Metal

CO₂ laser cutters use a gas laser beam, which is great for non-metals like wood or plastic. But metal? It’s tricky. Metals reflect most of the CO₂ laser’s energy, so low-power CO₂ cutters struggle to even make a mark. High-power ones can cut thin metals (like 0.5mm steel), but it’s slow and not precise. For thick or reflective metals (aluminum, copper), forget it—they’ll just bounce the laser back.

What Materials Do CO₂ Lasers Excel At?

While metal isn’t their strong suit, CO₂ laser cutters shine with non-metals:

Plastics (acrylic, PVC)

Wood and fabrics

Paper and cardboard

They’re perfect for crafts, signage, or textile projects. But if metal’s on your list, you need a better tool.

Why Fiber Optic Laser Cutting Machine is Better for Metal

Here’s where the Fiber Optic Laser Cutting Machine steps in. It uses a fiber laser that’s absorbed by metal, not reflected. This means:

Cuts thick metals (up to 20mm steel) easily.

Handles reflective metals like copper or aluminum smoothly.

Faster and more precise than CO₂ for metal jobs.

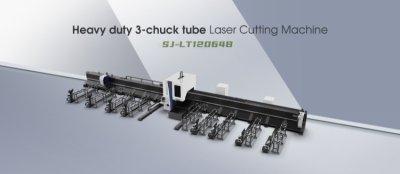

Even a metal tube laser cutter, often a type of Fiber Optic Laser Cutting Machine, excels at shaping metal pipes—something a CO₂ cutter can’t match.

Final Thoughts: Choosing the Right Tool

CO₂ laser cutters are awesome for non-metals, but metal? Stick with a Fiber Optic Laser Cutting Machine. It’s designed to tackle metal’s challenges, from thin sheets to thick tubes. For metal projects, the Fiber Optic Laser Cutting Machine is the clear winner in speed, precision, and versatility.