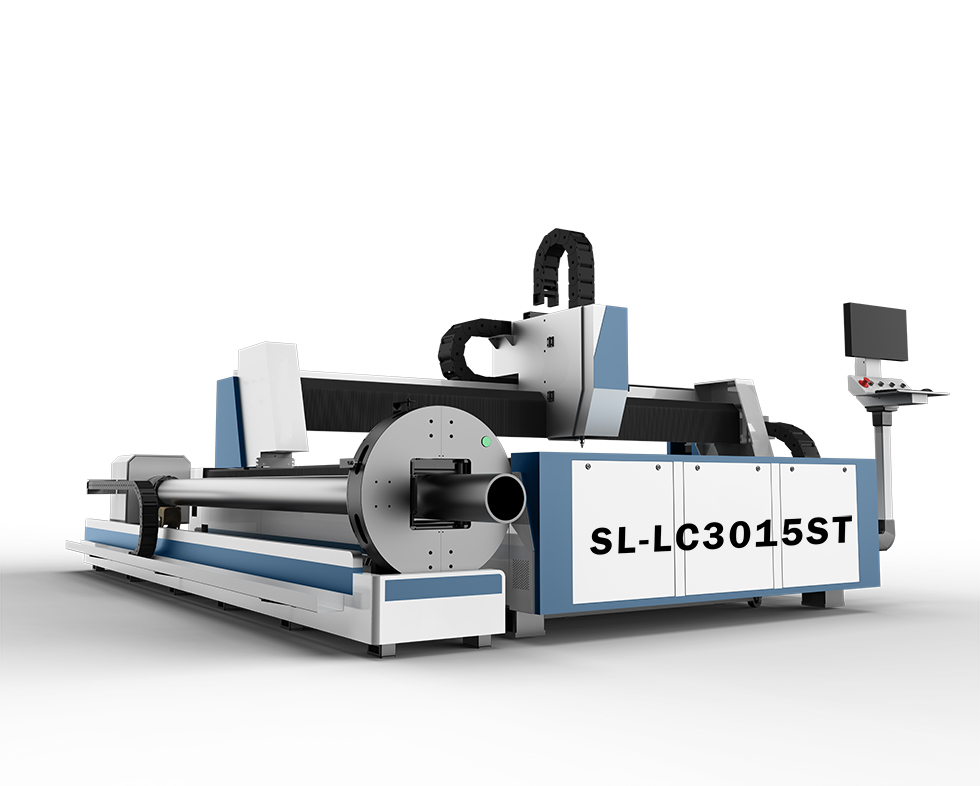

Regarding the Sheet and Tube Fiber Laser Cutting Machine

In what situations is it more suitable to use a combined sheet and tube fiber laser cutting machine?

In actual metal processing production, some customers have both the need to cut plates and pipes. Hence, a type of combined sheet and tube fiber laser cutting machine has emerged on the market. However, not all industries are suitable for purchasing such machines that can cut both pipes and plates. Whether to buy one depends on specific cutting requirements.

Advantages of combined sheet and tube fiber laser cutting machines:

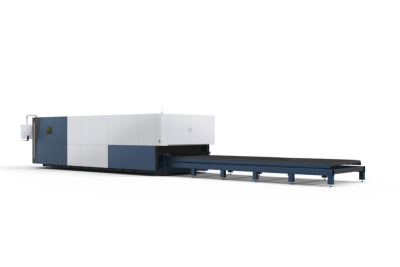

Combined sheet and tube fiber laser cutting machines are equipped with dual platforms for plate cutting and pipe cutting, enabling dual-purpose processing of plates and pipes. They are easy to operate, save space and usage costs. The processing process can switch between plate cutting and pipe cutting at any time, significantly improving production efficiency. If both plate and pipe processing are involved, but pipe processing only accounts for a small portion, this type of combined machine with a small footprint and low investment cost can be chosen.

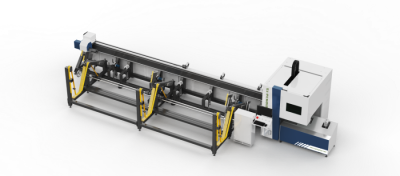

However, plate cutting and pipe cutting cannot be carried out simultaneously. To ensure the cutting accuracy of the plate cutting function, the space reserved for the pipe cutting function is relatively small, making it difficult to configure servo brackets, pneumatic lifting devices, and front material receiving racks. Therefore, when the volume of pipe processing is large and intensive, it is still recommended to choose a professional laser pipe cutting machine. Compared with the pipe cutting function of the combined pipe and plate machine, professional pipe cutting machines have certain advantages in terms of cutting accuracy and speed.

Working principle:

The working principle of the pipe and plate integrated laser cutting machine is to achieve cutting by means of the highly concentrated energy of the laser beam. The process is as follows: the laser beam is focused on the surface of the pipe or plate, forming a tiny action point with extremely high energy. Under the effect of this action point, the corresponding part of the pipe or plate will instantly melt and evaporate, thereby completing precise cutting. This process is highly precise and can achieve micron-level cutting accuracy.

Application fields:

- Automobile manufacturing industry: Car bodies, chassis frames, etc.

- Aerospace industry: Processing metal materials of different shapes to meet the processing needs of high-strength alloy materials.

- Energy equipment industry: Production of wind power generation and nuclear power equipment, etc.

- Machinery and equipment manufacturing: High-precision processing of complex-shaped or large-sized plates and pipes, etc.