How Many Types of Metal Cutting Machine Are There?

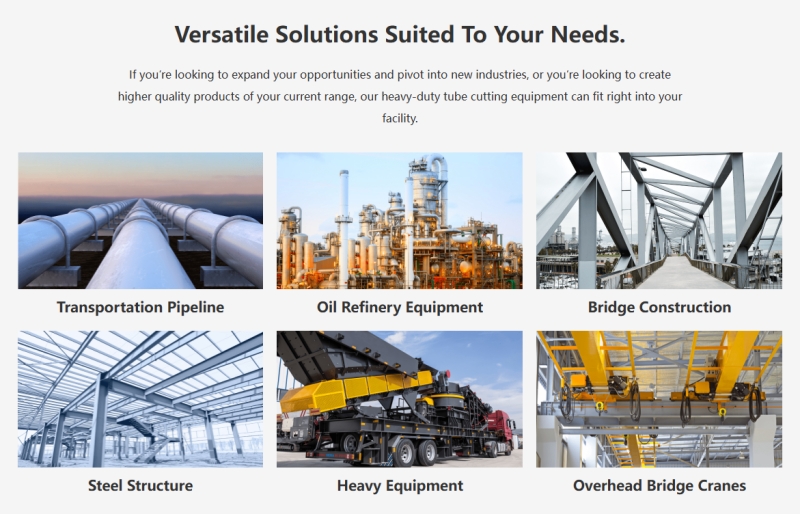

Metal cutting processes are the central pillars of raw material processing. Every manufacturing industry uses metal materials or tools.

Therefore, metal cutting processes power the entire manufacturing sector directly or indirectly.

There are countless applications of metal cutting processes, each with specific requirements. Therefore, many different types of metal

cutting processes like fiber laser and waterjet cutting have emerged in the industry.

This article will discuss the various metal cutting methods and how to choose one for your requirement.

What is Metal Cutting?

Metal cutting is a subtractive metalworking process of dividing a metal workpiece into multiple parts using force or other erosion techniques.

The cutting action can be generated with blades or methods like electrical discharges, water jets and Fiber laser machines.

There are many different metal cutting processes. The four main categories are mechanical cutting, abrasive cutting, thermal cutting and

electrochemical cutting and all of them use different types of metal cutting machines and tools.

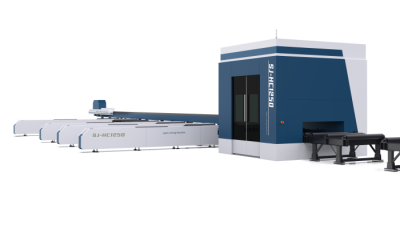

- Laser Cutting-

The laser-cutting process uses high-frequency light rays to melt the workpiece. Laser cutting is one of the most precise methods

due to the high narrow nature of the laser beam.

Advantages

• Laser cutting works on every material

• High precision

• Laser cutting can cut complex shapes Disadvantages

• Heat affected zones

• Laser cutting has severe limitations on material thickness

• Generation of dross due to oxidation of melted metals

Uses

• Automotive body parts

• Engines

• Panels

• Smartphone bodies