Essential Tools for Cutting Stainless Steel

Understanding the Basics of Stainless Steel

Before we dive into the intricacies of how to cut stainless steel, it’s important to refresh our understanding of this versatile material. Stainless steel stands out in the metal world due to its unique properties. Known for its high resistance to corrosion and staining, stainless steel is a popular choice in various industries, from kitchenware to construction.

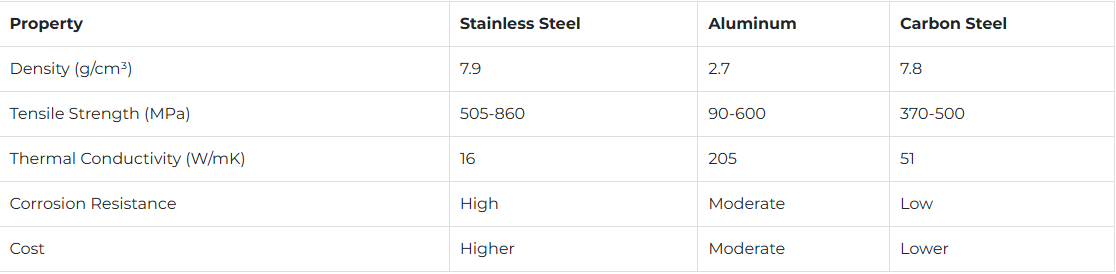

This resistance is primarily due to the alloy’s chromium content, which forms a passive layer of chromium oxide, preventing surface corrosion and stopping corrosion from spreading into the metal’s internal structure. When it comes to cutting stainless steel, especially thick stainless steel, understanding its properties compared to other metals is essential. The following is a comparative table showcasing how stainless steel differs from two other commonly used metals:

As we can see, stainless steel’s density and tensile strength make it a more robust and durable option than aluminum but less conductive in terms of heat. Compared to carbon steel, stainless steel offers superior corrosion resistance, an important factor in many applications.

However, these properties also make cutting stainless steel a task that requires precision and the right techniques. While steel, in general, is a common material, stainless steel’s specific characteristics must be considered during the cutting process. The hardness and strength of stainless steel demand tools and methods that can handle its robust nature without compromising the quality of the cut.

As we explore the methods for cutting stainless steel, these fundamental differences will guide our choice of tools and techniques, ensuring that every cut is clean, accurate, and efficient.

Essential Tools for Cutting Stainless Steel

Selecting the right tools is paramount when you’re set to cut stainless steel. Each tool has its unique advantages depending on the thickness of the stainless steel, the precision required, and the nature of the job.

The following is a rundown of the key tools you’ll need:

Circular saw: Ideal for cutting straight lines in stainless steel sheets, a circular saw equipped with metal cutting blades can handle medium to thick stainless steel. The key is to use a blade specifically designed for cutting metal to ensure a smooth, precise cut.

Plasma cutter: A plasma cutter is your best bet for thicker pieces of stainless steel. It uses a concentrated beam of energy to cut through the material, making it perfect for handling heavy-duty tasks with precision.

Angle grinder: Versatile and powerful, an angle grinder fitted with the right abrasive blade is suitable for cutting through both thin and thick stainless steel. It’s great for tasks that require more flexibility in cutting shapes.

Jigsaw: When you need to make more intricate cuts or work on curved designs in stainless steel, a jigsaw with a robust metal cutting blade is the tool of choice. It’s particularly useful for thinner stainless steel sheets.

Band saw: This tool is excellent for making longer cuts in stainless steel, especially when working with pipes or tubes. It’s effective for thin and thick materials, with the right blade selection crucial.

Rotary tool: A rotary tool is handy for making small, detailed cuts in stainless steel, especially in tight spaces, or for fine-tuning your work.

Laser cutter: Ideal for precise, intricate cuts in stainless steel. It uses a focused laser beam for clean, accurate cutting, suitable for detailed designs without affecting the metal’s properties.

Waterjet cutter: Uses high-pressure water with abrasives to cut stainless steel without heat, maintaining the metal’s integrity. Effective for thick materials and complex shapes.