How to Achieve High-Quality Cutting of Large-Sized Special-Shaped Pipes?

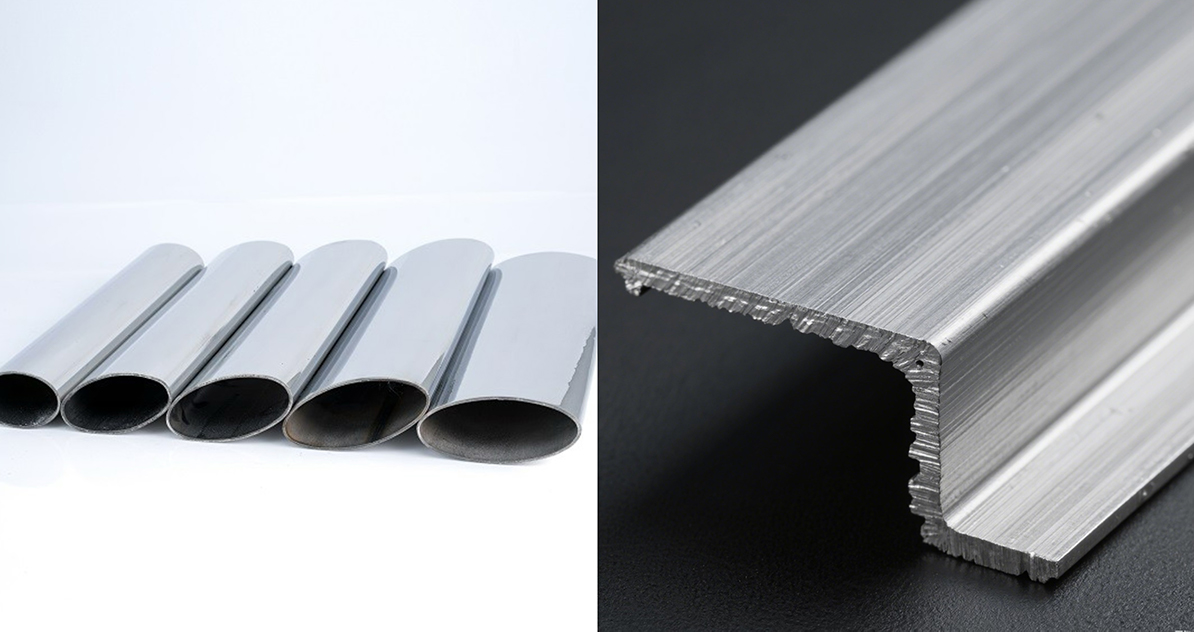

First, let’s understand what special-shaped pipes are.

Special-shaped pipes refer to pipes with non-circular cross-sections. Compared with traditional circular pipes, their cross-sections can be square, rectangular, elliptical, etc., and there are even more shape options, such as L-shaped, H-shaped, and so on. The cutting of irregular pipes is quite difficult. For some irregular pipes with complex shapes, traditional mechanical cutting methods are hard to meet the cutting requirements of high precision, high speed, and low cost.

Cutting Difficulties of Special-Shaped Pipes

1. When cutting L-shaped pipes, there are two cutting surfaces at different angles. Traditional mechanical cutting is prone to inclined cuts, and burrs are easily formed at the corners; rectangular pipes have many edges and corners in their cross-sections, so the angle of the cutting head must be precisely controlled during cutting to avoid cross-sectional deformation.

2. Due to the uneven curvature of elliptical pipes, traditional methods can hardly ensure that the cut is perpendicular to the axis.

3. The groove part of H-shaped pipes has a narrow space, making it difficult for traditional cutting tools to reach, which easily leads to incomplete cutting.

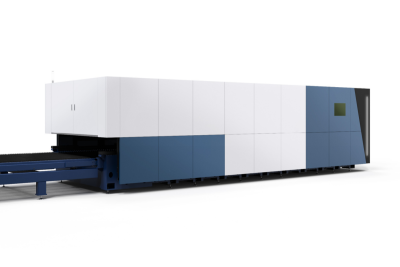

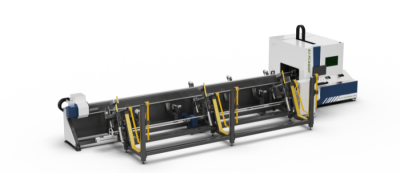

Cutting pipes of different shapes comes with many unique challenges that need to be overcome, Traditional Square Tube Laser Cutting Machine can no longer meet the processing requirements. In contrast, rotary laser pipe cutting machines not only cut pipes but also deliver results with high precision, high efficiency, and low cost.

Moreover, when dealing with large-sized special-shaped pipes, how can high precision and high efficiency be achieved in terms of their weight?

Advantages of High-Configuration Rotary Laser Pipe Cutting Machines

Chuck design: Equipped with a high-power laser source plus a self centering chuck setup, it ensures the stability of heavy-duty pipes during operation, preventing shifts that could affect precision when cutting or drilling.

Minimal leftover material: Controlled within ±3mm. This allows maximum utilization of pipes and helps reduce material cost issues.

Rotary laser head:

- Rotation range of the laser head: -360° ~ +360°

- Positioning accuracy of moving position: ±0.1mm

Advantages of the 5-axis system:

1. High-precision cutting.

2. High efficiency: Improves production efficiency and processing quality.

3.High flexibility: Thanks to its 5-axis linkage control, the laser pipe cutting machine offers exceptional flexibility—making it one of the key tools for precise processing of all kinds of special-shaped pipes.

4.Broad material compatibility: It is capable of processing stainless steel, carbon steel, copper, and various other metal pipe materials.

Application Fields

Large-sized special-shaped pipes are widely used in:

- The construction industry

- Machinery manufacturing

- Transportation

- The new energy field