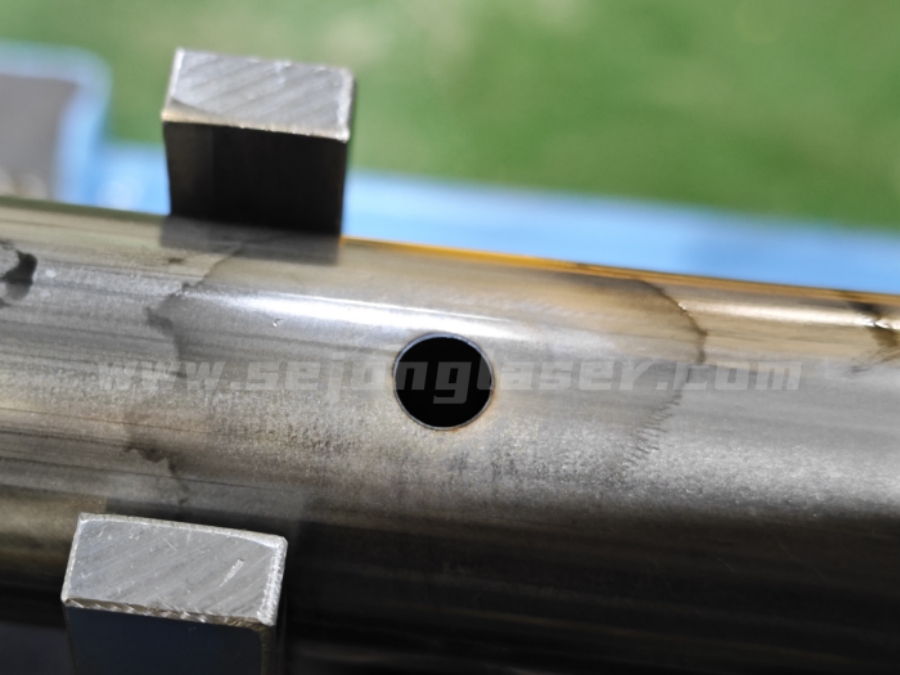

Why Bevel Cutting Small Holes Appear Irregular ?

When bevel cutting the small circular holes appear irregular, especially during bevel cutting in laser cutting

( Like the above picture showing), it can be attributed to several specific factors related to the complexity

of bevel cutting and the precision required for small features. Here are the potential causes and solutions:

Causes:

1. Bevel Angle and Laser Alignment:

• During bevel cutting, the laser head is tilted at an angle, which can affect the beam's focus and alignment.

If the alignment is not precise, the laser may not cut cleanly, leading to irregular holes.

2. Material Thickness and Heat Distribution:

• Bevel cutting often involves thicker materials, which can cause uneven heat distribution. This can result

in inconsistent melting and cutting, especially in small areas like holes.

3. Laser Beam Focus and Kerf Width:

• The focus of the laser beam becomes more critical in bevel cutting. If the beam is not properly focused,

the kerf (cut width) may vary, causing the hole to deviate from a perfect circle.

4. Assist Gas Flow and Pressure:

• The assist gas flow must be carefully controlled during bevel cutting. Incorrect pressure or flow can lead

to incomplete or irregular cuts, particularly in small holes.

5. Machine Dynamics and Stability:

• Bevel cutting requires precise movement of the laser head. Any mechanical instability or inaccuracy in the

machine's motion can result in irregular cuts.

6. Nozzle Condition and Positioning:

• The nozzle must be in optimal condition and correctly positioned for bevel cutting. A worn or misaligned

nozzle can disrupt the cutting process, leading to imperfect holes.

Solutions:

Optimize Laser Settings:

•Adjust the laser power, speed, and focus settings specifically for bevel cutting. Ensure the beam is properly focused for the material thickness and angle.

Ensure Proper Alignment:

• Calibrate the laser head and ensure it is precisely aligned for the bevel angle. Use alignment tools to verify the beam's position.

Control Assist Gas Parameters:

• Adjust the assist gas pressure and flow to match the requirements of bevel cutting. Ensure consistent gas delivery to the cutting area.

4. Stabilize the Machine:

• Check the machine's mechanical components for stability and accuracy. Regular maintenance and calibration

can help minimize vibrations and inaccuracies.

5. Inspect and Maintain the Nozzle:

• Regularly inspect the nozzle for wear or damage. Replace it if necessary and ensure it is correctly positioned

for bevel cutting.

6. Test and Adjust:

• Perform test cuts on scrap material to fine-tune the settings and identify any issues before cutting the

final workpiece.

By addressing these factors, you can improve the quality of small circular holes during bevel cutting in laser cutting processes.

If you have the questions for the fiber laser cutting machine welcome to ask our Engineers.