What is the Best Way to Cut the H Beam

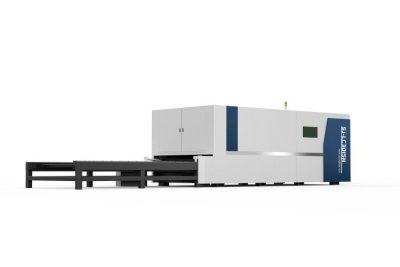

Fiber laser cutting machine can cut an H-beam (I-beam), but there are some important considerations to keep in mind. Laser cutting is highly precise and efficient for cutting metal, but its suitability for cutting H-beams depends on the size of the beam, the type of laser cutter, and the beam's thickness.

1. Smaller H-Beams:

- Laser cutters can easily cut smaller H-beams, especially if the beam fits within the machine's cutting bed and the thickness of the metal is within the laser's capacity (typically up to 25 mm for high-powered industrial lasers).

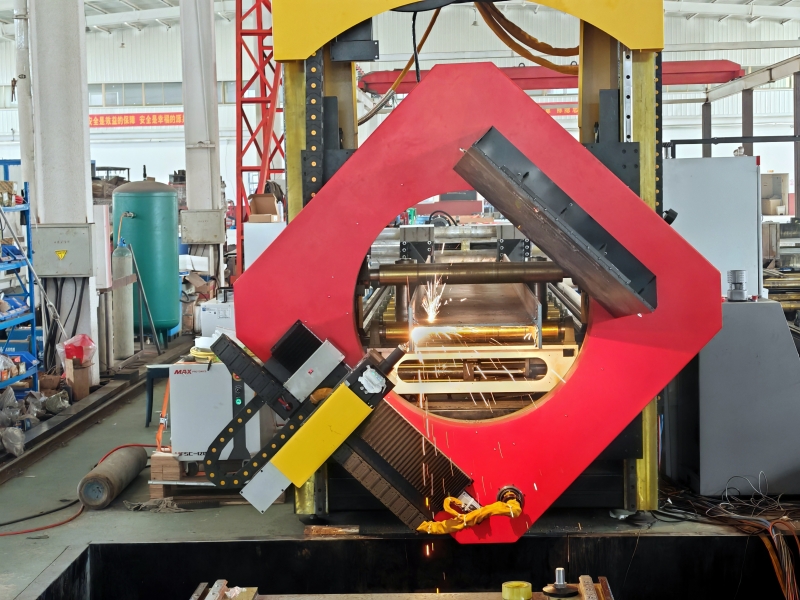

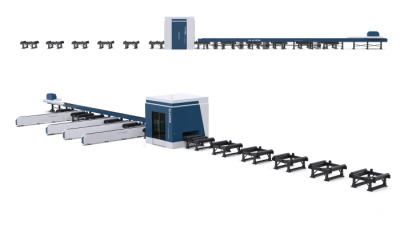

2. Larger H-Beams:

- Larger H-beams may not fit into standard laser cutting machines due to their size and shape. Specialized laser cutting systems or robotic laser cutters may be required for larger beams.

3. Thickness Limitations:

- Laser cutters are best suited for cutting metal up to a certain thickness. For example:

- Fiber lasers can typically cut steel up to 20-25 mm thick.

- CO2 lasers are better for thinner materials.

- If the H-beam's flange or web is thicker than the laser's capacity, alternative methods (like plasma cutting or oxy-acetylene cutting) may be more suitable.

---Advantages of Laser Cutting H-Beams:

Precision: Laser cutting provides extremely accurate and clean cuts, which is ideal for projects requiring tight tolerances.

Speed:Laser cutting is faster than many traditional methods for thinner materials.

Minimal Heat-Affected Zone (HAZ): Laser cutting produces a smaller HAZ compared to methods like oxy-acetylene cutting.

No Tool Wear: Unlike mechanical cutting methods, laser cutting does not involve physical contact with the material, so there is no tool wear.

---Disadvantages of Laser Cutting H-Beams:

- Size Limitations:Standard laser cutting machines may not accommodate large H-beams due to their shape and size.

- Thickness Limitations: Laser cutters struggle with very thick materials, which are common in heavy-duty H-beams.

- Cost: Industrial laser cutting machines are expensive and may not be cost-effective for small-scale or occasional use.

---Alternative Methods for Cutting H-Beams:

If laser cutting is not feasible due to size or thickness limitations, consider these alternatives:

1. Plasma Cutting:** Ideal for thick materials and large beams.

2. Oxy-Acetylene Cutting:** Suitable for very thick steel but requires skill.

3. Angle Grinder or Circular Saw:** For smaller beams or less precise cuts.

4. Hydraulic Shear or Ironworker:** For industrial-scale cutting.

---Conclusion:

Laser cutting is an excellent option for cutting smaller H-beams or when high precision is required. However, for larger or thicker H-beams, other methods like plasma cutting or oxy-acetylene cutting may be more practical. Always consider the size, thickness, and project requirements before choosing a cutting method.