How to Choose a Suitable Laser Beam?

CO2 LASER:

Speaking of the appropriate laser types and materials, the CO2 laser is versatile and practical for various materials

such as steel, stainless steel, wood, plastics,glass, and certain non-ferrous metals, being efficient up to a thickness

of approximately 20–25 mm.

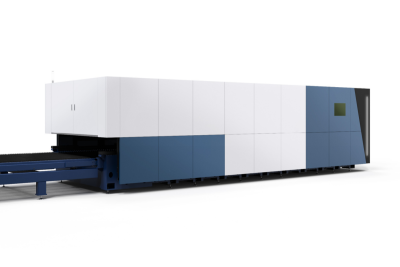

FIBER LASER CUTTING

On the other hand, the fiber optic laser is excellent for cutting reflective metals such as aluminum, brass, and

copper, being more efficient for smaller thicknesses. However, it can cut up to 30 mm, depending on the power.

SOLID-STATE LASER

Finally, solid-state lasers, such as Nd: YAG and Nd: YVO4, are ideal for materials such as metals, ceramics, and plastics

and are preferred for thinner thicknesses, particularly in applications that require high precision, such as electronics and micro-fabrication.

This range of technologies makes laser cutting find applications in various industries. It is used to produce automotive, aeronautical, and heavy machinery components and

manufacture custom parts for vertical sectors. Even in construction and architecture, it is used to create decorative elements, facades, and structural components with great precision,

a field in which many metalworking manufacturers have found many projects.

Producing small, precise electronic components, including printed circuit boards and mobile devices, is critical in electronics and microcomponent manufacturing.

Likewise, in medicine and biotechnology, it is used to manufacture surgical instruments and components for implants, as well as to cut biocompatible materials