Exploring Laser Sheet Cutting Machine

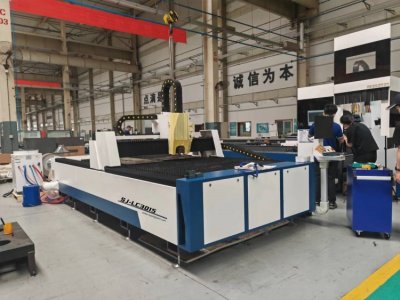

Laser Sheet Cutting Machine SL-LC3015

1. How it works

SL-LC3015 is a precision device for efficient, precise cutting of various flat materials. The working principle is mainly based on laser cutting technology, which uses a high-energy-density laser beam to locally irradiate the material, causing it to melt, evaporate or burn rapidly to achieve cutting. To meet customers' demands for cutting various patterns on flat materials, it has become one of the popular products in the laser market, with the advantage of high-volume, high-quality cutting. Now let's take a look at SL LASER's Sheet and Tube Laser Cutting Machine. SL-LC3015

2 Product Advantage of configuration

In order to meet requirements such as efficiency and precision, the configuration of the machine is a crucial and critical part, and it is the most concerned aspect for customers. The main configuration of the SL-LC3015, as one of the advantages, is summarized in three major parts: laser source, laser head, and segmented matrix. First up is the laser source

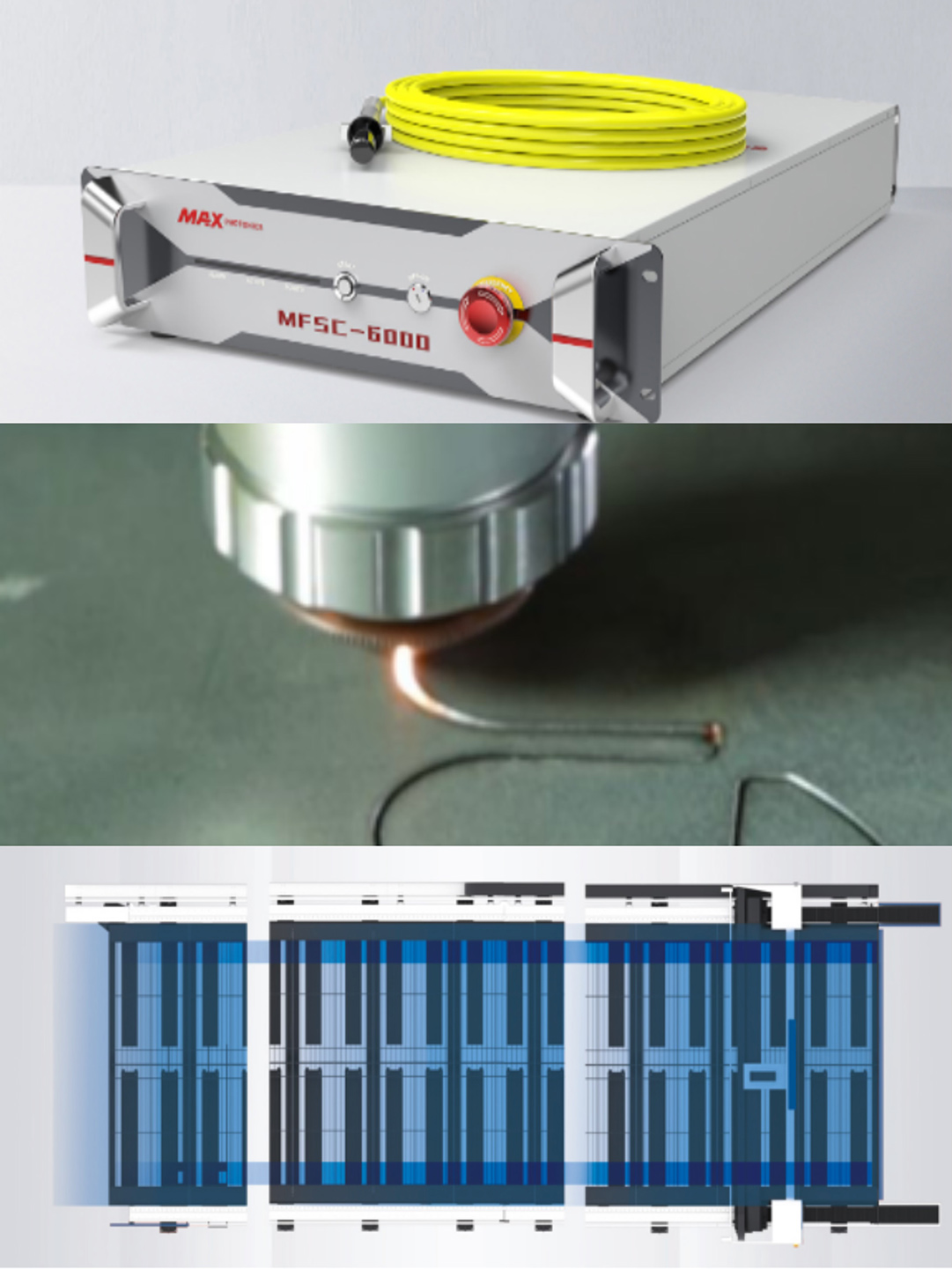

1) Laser source

The photoelectric conversion reaches 25%-30%

We have excellent pulse function for energy stability.

Long lifespan, high precision, pump source lifespan about 100,000 hours.

2) Laser head. High demands on the laser head are essential for achieving precise cutting.

Smooth and efficient airflow design

Achieve autofocus

Multiple protection lenses protect the collimating lens

Drawer-type frame: Protective lens for easy replacement

With a variety of fiber optic interfaces such as QBH and QD, it fits a wide range of mainstream lasers

3) Segmented matrix

During the cutting process, dust and residue may occur, which can affect both the laser head and the working environment of the on-site staff. Therefore, regarding the ventilation system. We use double-row, multi-row high-sealing partitions, 360° strong adsorption, filtering harmful gases, smoke and dust, etc. High-precision conveyor systems: High-precision reducers, precision linear guides, high-precision racks, ball screws and other high-quality components build a complete set of high-precision conveyor systems.

The above can achieve the high performance, low failure rate, long service life and other advantages of SL-LC3015. There are also many configurations and machine design tricks that have not been disclosed, such as enhancing the safety of on-site operators. In addition to safety operation training for our after-sales staff, we will have cameras in the laser head cutting area to ensure the safety of personnel operation and make sure there is no danger, etc. Customers are welcome to contact SL LASER to unlock more.

3 Above is an introduction to the main configuration of the SL-LC3015.

To meet customers' requirements for different material sizes or other aspects of the flatbed cutting machine, we have also prepared different feature models of flatbed laser cutting machines for customers

1) Exchange platform with cover:

The dual-platform exchange system of a laser flatbed cutter enables platforms to be used alternately. This satisfies customer requirements for accelerated sheet processing, reducing cycle times and enhancing productivity. The cover can prevent cutting sparks from flying, ensuring a smokeless and pollution-free cutting process. The laser is separated from the operator to avoid injury to the human body. Double protect the working environment.

2)Dual-platform exchange system and Tube Laser Cutting Machine without outer cover tube sheet integrated:

It can meet the requirements of cutting plates and tubes on the same machine, significantly reducing costs.

3)Extra-large format ground rail machine

Complete high-precision cutting requirements for oversized plates. In addition to the model, we can customize the size according to the customer's requirements.

4 Application Areas

1) Automobile manufacturing: from complex body panels to precise engine components.

2) Aerospace industry: Using SL-LC3015 cutting technology to manufacture aircraft components.

3) Furniture manufacturing, doors and Windows, etc., complex pattern cutting, etc.